Through more than two decades of continuous research and field experience, Solidfog has mastered the science of VH₂O₂ decontamination. Our deep understanding of micro-condensation and its influence on sporicidal performance allows us to design and control processes that deliver consistent, validated results in every environment.

Let’s explore the scientific principles that underpin VH₂O₂ airborne surface disinfection and explain why controlled micro-condensation is at the heart of an effective decontamination process.

Factors influencing the VH2O2 decontamination process

VH₂O₂ is generated from an aqueous solution of hydrogen peroxide and water. Commercial hydrogen peroxide solutions usually range from 6% to 35% in concentration, but concentration alone does not determine the sporicidal effect. Although higher environmental concentrations of H₂O₂ generally increase lethality, other variables such as temperature and relative humidity also have a significant impact.

As temperature rises, the lethality of H₂O₂ tends to improve, though this effect remains moderate under typical ambient conditions. Relative humidity is a much more influential parameter. When the atmosphere contains high humidity, meaning a greater proportion of water in the gas phase, the available space for achieving a high H₂O₂ concentration decreases. It might therefore seem logical to seek maximum H₂O₂ concentration under conditions of minimal humidity.

However, research has shown that equivalent levels of lethality can also be achieved with lower concentrations of H₂O₂ if humidity is increased. Higher relative humidity can compensate for lower peroxide concentrations. Beyond a certain point, additional humidity no longer improves results, but avoiding the need for dehumidification while still achieving the required sporicidal effect is a major advantage. The essential point is to find the right balance between humidity and concentration.

The belief that maximum lethality requires the highest possible H₂O₂ concentration is therefore inaccurate. A strong biocidal effect can be achieved at lower peroxide concentrations if humidity levels are properly adjusted.

Micro-condensation and its relationship with the sporicidal effect

The positive influence of humidity on lethality can be explained by a phenomenon known as micro-condensation, which occurs as the atmosphere approaches saturation. VH₂O₂ consists of hydrogen peroxide and water, two components with very different physical and chemical properties. The vapour pressure of water is about one hundred times greater than that of hydrogen peroxide, which means that water evaporates much faster. Gaseous hydrogen peroxide is less stable than water vapour and therefore condenses first. This is why it is inaccurate to describe vaporised H₂O₂ simply as a gas.

When VH₂O₂ is introduced into an area at ambient temperature, condensation occurs once saturation is reached, even though it may not be visible. This invisible condensation is called micro-condensation.

Micro-condensation creates the sporicidal effect because the condensed droplets are rich in hydrogen peroxide, containing around seventy-five percent H₂O₂. This happens because hydrogen peroxide condenses before water. In addition, due to a process known as nucleation, the condensation forms preferentially on microorganisms or small particles in the air or on surfaces. The microorganisms become surrounded by a microscopic liquid film with a high concentration of hydrogen peroxide, and this film produces the sporicidal effect.

Some researchers have introduced the term MCHP, meaning Micro-Condensed Hydrogen Peroxide, to describe the true active state of the agent. According to this concept, the vapour acts only as a carrier that delivers the micro-condensate, while the micro-condensate itself is the effective sporicidal form because of its high peroxide concentration.

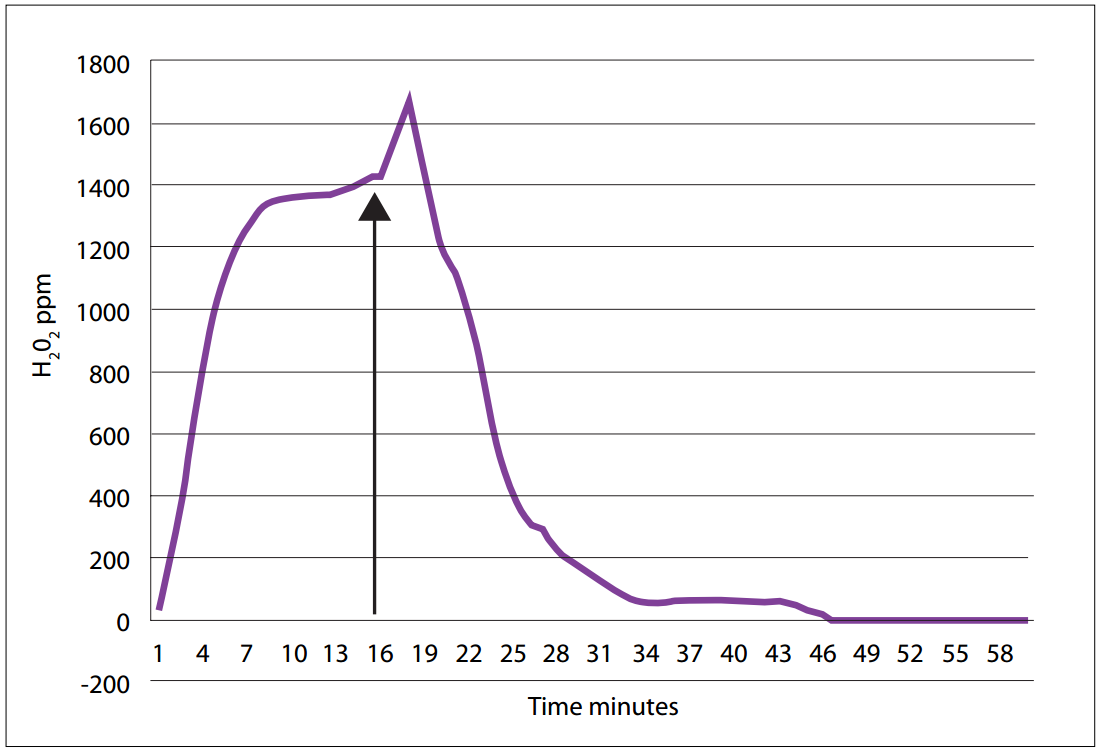

Correlation between concentration and cycle time

When VH₂O₂ is introduced into a space under ambient conditions, a natural balance is reached in which micro-condensation forms within the environment. The relationship between concentration and condensation directly affects the duration of the cycle. Higher concentrations of H₂O₂ tend to achieve microbial inactivation more rapidly, but they also require longer aeration phases to ensure safe re-entry. The optimal cycle is therefore the one that achieves the required lethality while maintaining a practical and efficient recovery time.

Atomization as cold vaporisation

Atomization is an alternative method of vaporisation. It involves injecting the liquid solution through a nozzle and mixing it precisely with compressed air. When released, the mixture forms a fine mist containing a large number of micro-droplets that disperse through kinetic energy. These droplets generally range from five to twenty micrometres in diameter, with an average size of about ten micrometres.

The smallest droplets evaporate almost immediately, while larger ones travel further due to their kinetic energy. They remain suspended in the air without wetting surfaces and are light enough to float. When they strike a surface, they rebound instead of bursting and continue to disperse until they fully evaporate. This non-wetting behaviour results from the relationship between the surface tension of the droplet and its volume. As a result, the process creates a fine, dry mist capable of maintaining a uniform and stable VH₂O₂ concentration throughout the treated area. This ensures even micro-condensation and consistent sporicidal performance.

For 20 years, Solidfog has mastered the science of VH₂O₂. By controlling micro-condensation with precision, we transform theory into proven biodecontamination performance.