NeutraMist®

The catalytic solution

The aeration phase of a decontamination cycle with VH2O2 is usually the longest one, especially in large rooms or areas. Cycle times will mainly depend on the capacity and design of the HVAC system (either 100% extraction or recirculation). With the Neutramist catalytic system it would be possible to reduce the aeration time consequently.

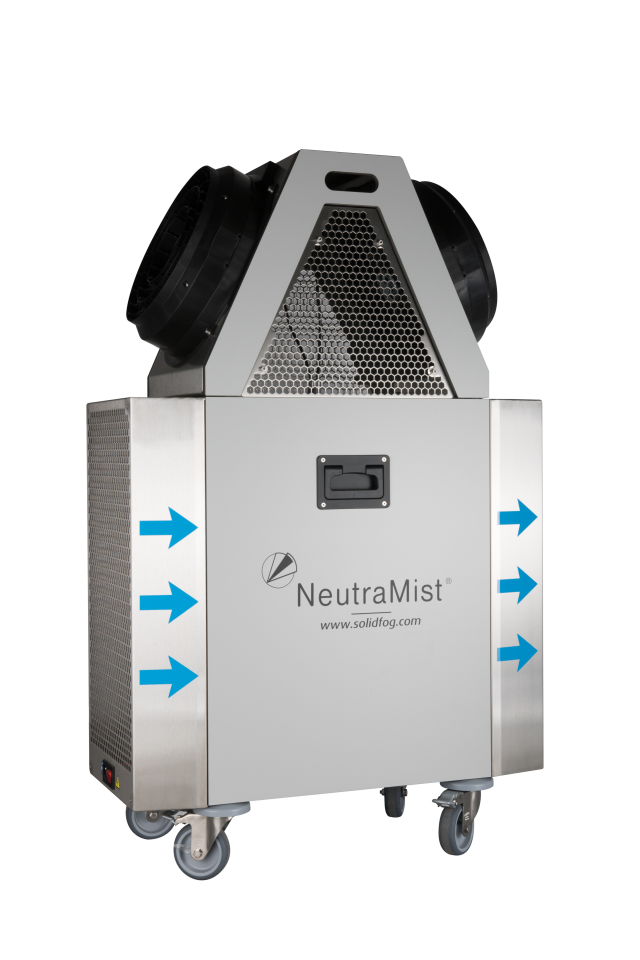

The NeutraMist® is in its mobile design made of HPL panels (high pressure laminate panels) including a ceramic honeycomb structure with active catalytic surface, a centrifugal fan system and air outlet through an HEPA filter panel. The unit can work synchronised with our DosyMist XL® units.

Depending on the VH2O2 concentration at the inlet flange, the remaining percentage of VH2O2 may vary from 0,0 to 5,0 ppm after one passage through the catalytic element.

The NeutraMist® can be supplied as catalytic element for integration in applications such as MAL, Isolators, pass-boxes, etc. and in such case, the configuration will allow to guarantee less than 1 ppm after one passage

Key features

Cost savings

Cost savings through a reduced use of ventilation system in the cleanroom being decontaminated.

Low power consumption

Lower power consumption compared with the need to use the HVAC system during all the aeration phase.

Great lifetime

As soon as the catalytic element remains properly protected from dust, the lifetime of the solution remains difficult to be fixed.

No maintenance needed - except for inlet and outlet filters.